How to maintain a polished concrete floor

- Category: Product News

The rise in popularity of polished concrete floors is due to the extensive list of benefitting characteristics the flooring products encompass. The usage and specification of concrete flooring products have increased in both the commercial building sector as well as being used in people’s homes to achieve varied design outcomes.

The rise in popularity of polished concrete floors is due to the extensive list of benefitting characteristics the flooring products encompass. The usage and specification of concrete flooring products have increased in both the commercial building sector as well as being used in people’s homes to achieve varied design outcomes.

One of the most notable characteristics of polished concrete floors is the low level of maintenance required to keep the floors appearing and functioning as well as the day they were first finished.

Polished concrete floors are not completely maintenance free. However they are generally easier to maintain when compared with other floor coverings. In saying this, they do require regular attention in terms of a routine cleaning schedule. The required products and tools differ to other floor coverings, primarily due to concrete being a natural product.

The frequency of maintenance required largely depends on the amount of traffic the floor is likely to receive. For example, the maintenance needs of a residential floor are much different than a floor in a high-traffic, commercial or retail environment. For project specific instructions please contact your flooring contractor.

Tips:

Tips:

- Important! Follow the maintenance schedule provided and recommended by your flooring contractor, as the flooring products utilised on each project are different, before undertaking any other instructions.

- Routine. A simple and quick maintenance routine (see general recommended routine below) will help to enhance shine. If a floor starts to lose its shine, simply buffing the surface with a high speed floor burnisher and appropriate maintenance pad will improve the lustre.

- Tools. Make sure you have the right tools for the job. For dusting/mopping use a microfibre pad/mop. Dirt particles can act as an abrasive, which can ruin the clarity and shine of a polished concrete floor. Avoid abrasive brushes and/or scourer’s!

- Products. Always use neutral cleaning products. No acids, no citrus, nothing harsh or harmful. Whilst polished concrete has a strong defence system to resist these products, they will damage/corrode the floor or etch the surface over time.

- Spills. Clean spills quickly! If you spill red wines or citric acids, in particular, on your polished concrete floor remove them as quickly as possible to prevent permanent staining. Follow the recommended routine below.

- Sealers (sealer dependant) form a good barrier against stains but they are not 100% stain resistant!

Recommended Maintenance Schedule:

Recommended Maintenance Schedule:

- Remove surface grit. Removing topical dust and dirt with a microfiber mop/pad is the most critical part of maintaining a polished concrete floor. The required frequency varies depending on the environment, build up and usage of the floor. However, a daily dust would be highly recommended. This is due to the ability of topical dirt to act as an abrasive, dulling the surface of the floor over time.

- Cleaning the surface. Once the topical dirt is removed it is recommended to mop/auto scrub the polished concrete floor to clean the surface. Use a poly cotton or microfibre mop with warm water and a neutral floor cleaner. Avoid using general supermarket cleaners as they general contain harsh chemicals. (Acids, ammonia, alkali)

- Prevention. Dust, dirt and grit are abrasives that may cause eventual damage to your floor. Using prevention methods such as doormats or by always removing footwear before entering (in residential environments) help to stop dirt trafficking over your floor. This will aid in preventing surface scratching and premature aging of your floors as well as minimise the amount of cleaning required.

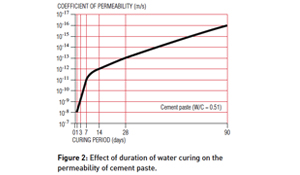

Figure 2 illustrates the effect of different periods of water curing on the permeability of cement paste. As may be seen, extending the period of curing reduces the permeability.

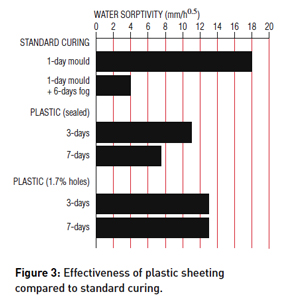

Figure 2 illustrates the effect of different periods of water curing on the permeability of cement paste. As may be seen, extending the period of curing reduces the permeability. For decorative finishes or where colour uniformity of the surface is required sheeting may need to be supported clear of the surface if hydration staining is of concern. This can be achieved with wooden battens or even scaffolding components, provided that a complete seal can be achieved and maintained.

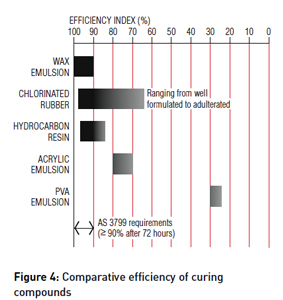

For decorative finishes or where colour uniformity of the surface is required sheeting may need to be supported clear of the surface if hydration staining is of concern. This can be achieved with wooden battens or even scaffolding components, provided that a complete seal can be achieved and maintained. They are an efficient and cost-effective means of curing concrete and may be applied to freshly placed concrete or that which has been partially cured by some other means. However, they may affect the bond between concrete and subsequent surface treatments. Special care in the choice of a suitable compound needs to be exercised in such circumstances. The residue from some products may prevent the adhesion of flooring products and tiles onto the concrete surface.

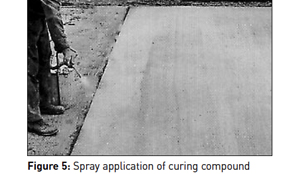

They are an efficient and cost-effective means of curing concrete and may be applied to freshly placed concrete or that which has been partially cured by some other means. However, they may affect the bond between concrete and subsequent surface treatments. Special care in the choice of a suitable compound needs to be exercised in such circumstances. The residue from some products may prevent the adhesion of flooring products and tiles onto the concrete surface. Pigmented compounds also help ensure complete coverage and are advantageous in helping concrete surfaces reflect rather than absorb heat. Figure 5 shows pressure spraying of a whitepigmented curing compound.

Pigmented compounds also help ensure complete coverage and are advantageous in helping concrete surfaces reflect rather than absorb heat. Figure 5 shows pressure spraying of a whitepigmented curing compound.

Specifying Slip Resistance

Specifying Slip Resistance

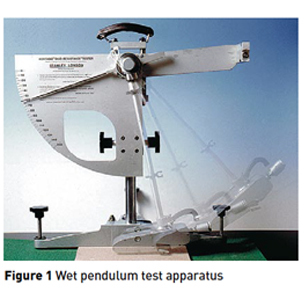

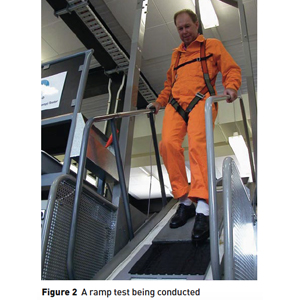

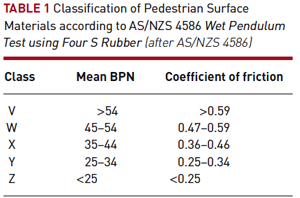

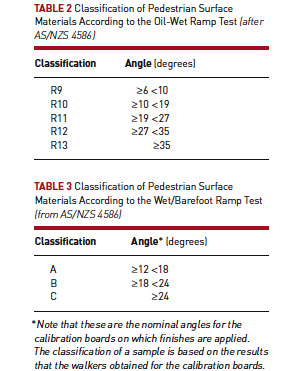

The wet pendulum test may be used within a range of ±10° from level (slope of about 1 in 5.7).When assessing whether or not a sloping surface has adequate slip resistance, use the same procedure as in the examples above, and compare] the obtained result with the required BPN . The AS/NZS 4586 wet pendulum test can be used to check the compliance of new surfaces, while the AS/NZS 4663 wet pendulum test can be used to monitor changes in the slip resistance over time. For measuring the slip resistance of slopes steeper than 10°, a flatter area either at the top or bottom of the ramp (having the same surface texture and roughness as the slope) may need to be used for the test.

The wet pendulum test may be used within a range of ±10° from level (slope of about 1 in 5.7).When assessing whether or not a sloping surface has adequate slip resistance, use the same procedure as in the examples above, and compare] the obtained result with the required BPN . The AS/NZS 4586 wet pendulum test can be used to check the compliance of new surfaces, while the AS/NZS 4663 wet pendulum test can be used to monitor changes in the slip resistance over time. For measuring the slip resistance of slopes steeper than 10°, a flatter area either at the top or bottom of the ramp (having the same surface texture and roughness as the slope) may need to be used for the test.