DATA SHEET: Curing of concrete

- Published in Product News

Introduction

Curing is the process of controlling the rate and extent of moisture loss from concrete during cement hydration. It may be either after it has been placed in position (or during the manufacture of concrete products), thereby providing time for the hydration of the cement to occur. Since the hydration of cement does take time – days, and even weeks rather than hours – curing must be undertaken for a reasonable period of time if the concrete is to achieve its potential strength and durability. "Curing is the process of controlling the rate and extent of moisture loss from concrete during cement hydration." Curing may also encompass the control of temperature since this affects the rate at which cement hydrates.

The curing period may depend on the properties required of the concrete, the purpose for which it is to be used, and the ambient conditions, ie the temperature and relative humidity of the surrounding atmosphere. Curing is designed primarily to keep the concrete moist, by preventing the loss of moisture from the concrete during the period in which it is gaining strength. Curing may be applied in a number of ways and the most appropriate means of curing may be dictated by the site or the construction method.

Curing by preventing excessive loss of moisture from the concrete: either by

- leaving formwork in place

- covering the concrete with an impermeable membrane after the formwork has been removed

- by the application of a suitable chemical curing agent (wax etc)

- or by a combination of such methods n Curing by continuously wetting the exposed surface thereby preventing the loss of moisture from it. Ponding or spraying the surface with water are methods typically employed to this end.

Effect of duration of curing on properties of concrete

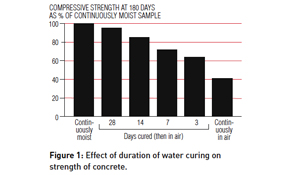

The strength of concrete is affected by a number of factors, one of which is the length of time for which it is kept moist, ie cured. Figure 1 illustrates this, comparing the strength (at 180 days) of concrete for which the surfaces have been:

- kept moist for 180 days;

- kept moist for various periods of time and allowed to dry out; and

- allowed to dry out from the time it was first made. As may be seen in this example, concrete

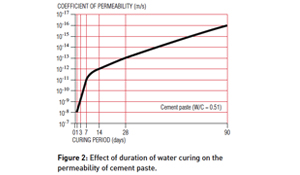

- allowed to dry out immediately achieves only 40% of the strength of the same concrete water cured for the full period of 180 days. Even three days water curing increases this figure to 60%, whilst 28 days water curing increases it to 95%. Keeping concrete moist is therefore, a most effective way of increasing its ultimate strength. Concrete that is allowed to dry out quickly also undergoes considerable early age drying shrinkage. Inadequate or insufficient curing is one of main factors contributing to weak, powdery surfaces with low abrasion resistance. The durability of concrete is affected by a number of factors including its permeability and absorptivity. Broadly speaking, these are related to the porosity of the concrete and whether the pores and capillaries are discrete or interconnected. Whilst the number and size of the pores and capillaries in cement paste are related directly to its water-cement ratio, they are also related, indirectly, to the extent of water curing. Over time, water curing causes hydration products to fill, either partially or completely, the pores and capillaries present, and, hence, help to reduce the porosity of the paste.

Figure 2 illustrates the effect of different periods of water curing on the permeability of cement paste. As may be seen, extending the period of curing reduces the permeability.

Figure 2 illustrates the effect of different periods of water curing on the permeability of cement paste. As may be seen, extending the period of curing reduces the permeability.

Curing Methods

General Methods of curing concrete fall broadly into the following categories:

- Those that minimise moisture loss from the concrete, for example by covering it with a relatively impermeable membrane.

- Those that prevent moisture loss by continuously wetting the exposed surface of the concrete.

- Those that keep the surface moist and, at the same time, raise the temperature of the concrete, thereby increasing the rate of strength gain. This method is typically used for precast concrete products and is outside the scope of this data sheet.

Impermeable-membrane

Curing Formwork - Leaving formwork in place is often an efficient and cost-effective method of curing concrete, particularly during its early stages. In very hot dry weather, it may be desirable to moisten timber formwork, to prevent it drying out during the curing period, thereby increasing the length of time for which it remains effective.

It is desirable that any exposed surfaces of the concrete (eg the tops of beams) be covered with plastic sheeting or kept moist by other means. It should be noted that, when vertical formwork is eased from a surface (eg from a wall surface) its effectiveness as a curing system is significantly reduced.

Plastic sheeting - Plastic sheets, or other similar material, form an effective barrier against water loss, provided they are kept securely in place and are protected from damage. Their effectiveness is very much reduced if they are not kept securely in place. The movement of forced draughts under the sheeting must be prevented.

They should be placed over the exposed surfaces of the concrete as soon as it is possible to do so without marring the finish. On flat surfaces, such as pavements, they should extend beyond the edges of the slab for some distance, eg or at least twice the thickness of the slab, or be turned down over the edge of the slab and sealed.

For flat work, sheeting should be placed on the surface of the concrete and, as far as practical, all wrinkles smoothed out to minimise the mottling effects (hydration staining), due to uneven curing, which might otherwise occur. Flooding the surface of the slab under the sheet can be a useful way to prevent mottling. Strips of wood, or windrows of sand or earth, should be placed across all edges and joints in the sheeting to prevent wind from lifting it, and also to seal in moisture and minimise drying.

For decorative finishes or where colour uniformity of the surface is required sheeting may need to be supported clear of the surface if hydration staining is of concern. This can be achieved with wooden battens or even scaffolding components, provided that a complete seal can be achieved and maintained.

For decorative finishes or where colour uniformity of the surface is required sheeting may need to be supported clear of the surface if hydration staining is of concern. This can be achieved with wooden battens or even scaffolding components, provided that a complete seal can be achieved and maintained.

For vertical work, the member should be wrapped with sheeting and taped to limit moisture loss. As with flatwork, where colour of the finished surface is a consideration, the plastic sheeting should be kept clear of the surface to avoid hydration staining.

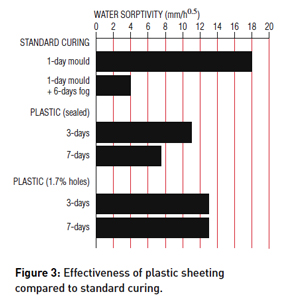

Care must also be taken to prevent the sheeting being torn or otherwise damaged during use. A minimum thickness is required to ensure adequate strength in the sheet; ASTM C 171 Sheet Materials for Curing Concrete specifies 0.01 mm. Figure 3 illustrates the lack of effectiveness of plastic sheeting with holes equivalent to only 1.7% of the sheet’s surface area.

Plastic sheeting may be clear or coloured. Care must be taken that the colour is appropriate for the ambient conditions. For example, white or lightly coloured sheets reflect the rays of the sun and, hence, help to keep concrete relatively cool during hot weather. Black plastic, on the other hand, absorbs heat to a marked extent and may cause unacceptably high concrete temperatures. Its use should be avoided in hot weather, although in cold weather its use may be beneficial in accelerating the rate at which the concrete gains strength.

Clear plastic sheeting tends to be more neutral in its effect on temperature (except in hot weather, where it fails to shade the surface of the concrete) but tends to be less durable than the coloured sheets, thereby reducing its potential for re-use.

Membrane-forming curing compounds - Curing compounds are liquids which are usually sprayed directly onto concrete surfaces and which then dry to form a relatively impermeable membrane that retards the loss of moisture from the concrete. Their properties and use are described in AS 3799 Liquid Membrane-forming Curing Compounds for Concrete.

They are an efficient and cost-effective means of curing concrete and may be applied to freshly placed concrete or that which has been partially cured by some other means. However, they may affect the bond between concrete and subsequent surface treatments. Special care in the choice of a suitable compound needs to be exercised in such circumstances. The residue from some products may prevent the adhesion of flooring products and tiles onto the concrete surface.

They are an efficient and cost-effective means of curing concrete and may be applied to freshly placed concrete or that which has been partially cured by some other means. However, they may affect the bond between concrete and subsequent surface treatments. Special care in the choice of a suitable compound needs to be exercised in such circumstances. The residue from some products may prevent the adhesion of flooring products and tiles onto the concrete surface.

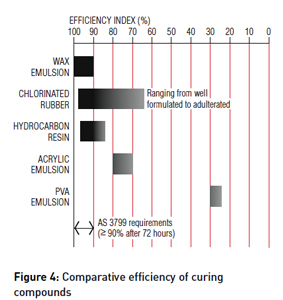

Curing compounds are generally formulated from wax emulsions, chlorinated rubbers, synthetic and natural resins, and from PVA emulsions. Their effectiveness varies quite widely, depending on the material and strength of the emulsion, as is illustrated in Figure 4. Note: Attention should be drawn to the very poor efficiency of PVA curing compounds.

When used to cure fresh concrete, the timing of the application of the curing compounds is critical for maximum effectiveness. They should be applied to the surface of the concrete after it has been finished, as soon as the free water on the surface has evaporated and there is no water sheen visible. Too early an application dilutes the membrane; too late results in it being absorbed into the concrete, with a consequent failure of the membrane to form.

They may also be used to reduce moisture loss from concrete after initial moist curing or the removal of formwork. In both cases, the surface of the concrete should be thoroughly moistened before the application of the compound to prevent its absorption into the concrete.

The use of curing compounds will not prevent formation of early age thermal cracking.

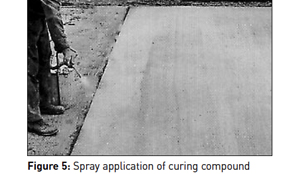

Curing compounds can be applied by hand spray, power spray, brush or roller. The type or grade of curing compound should be matched to the type of equipment available and the manufacturer’s directions followed. The rate of application should be uniform, with coverage normally in the range 0.20 to 0.25 litres/m2. Where feasible, two applications at right angles to each other will help ensure complete coverage.

Pigmented compounds also help ensure complete coverage and are advantageous in helping concrete surfaces reflect rather than absorb heat. Figure 5 shows pressure spraying of a whitepigmented curing compound.

Pigmented compounds also help ensure complete coverage and are advantageous in helping concrete surfaces reflect rather than absorb heat. Figure 5 shows pressure spraying of a whitepigmented curing compound.

It is extremely important to check the subsequent floor finish. Most curing compounds must be removed before the application of any applied floor finishes such as direct stick carpet and vinyl, epoxy or polyurethane coatings and ceramic tile adhesives.

Finally, it should be noted when using curing compounds that are solvent-based adequate ventilation must always be provided in enclosed spaces and other necessary safety precautions taken. Manufacturer’s recommendations should always be followed.

Internal curing compounds - These are incorporated into the concrete as an admixture hence known as internal curing compounds. They inhibit moisture loss and thereby improve long term strength and reduce drying shrinkage. Internal curing compounds are relatively new and care should be taken when utilised. They have been used in tunnel linings and underground mines to provide at least partial curing when traditional methods are difficult or even impossible to employ.

Water Curing

General - Water curing is carried out by supplying water to the surface of concrete in a way that ensures that it is kept continuously moist.

The water used for this purpose should not be more than about 5°C cooler than the concrete surface. Spraying warm concrete with cold water may give rise to ‘thermal shock’ that may cause or contribute to cracking.Alternate wetting and drying of the concrete must also be avoided as this causes volume changes that may also contribute to surface crazing and cracking.

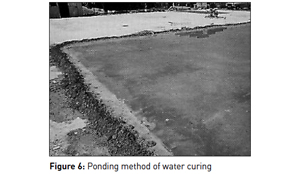

Ponding - Flat or near-flat surfaces such as floors, pavements, flat roofs and the like may be cured by ponding. A ‘dam’ or ‘dike’ is erected around the edge of the slab and water is then added to create a shallow ‘pond’ as shown in Figure 6. Care must be taken to ensure the pond does not empty due to evaporation or leaks.

Ponding is a quick, inexpensive and effective form of curing when there is a ready supply of good ‘dam’ material (eg clay soil), a supply of water, and the ‘pond’ does not interfere with subsequent building operations. It has the added advantage of helping to maintain a uniform temperature on the surface of the slab. There is thus less likelihood of early age thermal cracking in slabs that are cured by water ponding.

Sprinkling or fog curing - Using a fine spray or fog of water can be an efficient method of supplying additional moisture for curing and, during hot weather, helps to reduce the temperature of the concrete.

As with other methods of moist curing, it is important that the sprinklers keep the concrete permanently wet. However, the sprinklers do not have to be on permanently; they may be on an intermittent timer.

Sprinklers require a major water supply, can be wasteful of water and may need a drainage system to handle run-off. The alternative is to have a ‘closed’ system where the water is collected and recycled.

Sprinkler systems may be affected by windy conditions and supervision is required to see that all of the concrete is being kept moist and that no part of it is being subjected to alternated wetting and drying. This is not easy to achieve.

Wet coverings - Fabrics such as hessian, or materials such as sand, can be used like a ‘mulch’ to maintain water on the surface of the concrete. On flat areas, fabrics may need to be weighed down. Also, it is important to see that the whole area is covered. Wet coverings should be placed as soon as the concrete has hardened sufficiently to prevent surface damage. They should not be allowed to dry out as they can act as a wick and effectively draw water out of the concrete.

Fabrics may be particularly useful on vertical surfaces since they help distribute water evenly over the surface and even where not in contact with it, will reduce the rate of surface evaporation. Care should be taken however, that the surface of the concrete is not stained, perhaps by impurities in the water, or by the covering material.

New fabrics can leach fabric stains, pre‑washing should be essential. Prior to placement of any fabric – pre moisten to avoid wicking of moisture from the concrete that can result in the fabric texture negatively absorbed into the concrete surface.

Article courtesy of Cement Concrete & Aggregates Australia website - www.ccaa.com.au