DATA Sheet: Slip resistance of polished concrete surfaces - Part II: Specifying slip resistance

- Published in Product News

Specifying Slip Resistance

Specifying Slip Resistance

General - Slip resistance is typically specified by nominating an appropriate class from those listed in AS/NZS 4586 test methods. To assist with this decision, HB 197 Table 3 gives guidance on the appropriate classes of slip resistance for a variety of applications. The relevant classification and test method for various end uses is given below.

Since the wet pendulum test will always be used for conducting slip resistance audits (and accident investigations) it is recommended that the slip resistance of polished concrete be specified in terms of the AS/NZS 4586 wet pendulum classifications.

Sloping surfaces and ramps should be given special consideration. The Building Code of Australia requires that ramps must have a nonslip finish, and limits the maximum gradient of accessible ramps for disabled access to 1 in 14. In any other case, the maximum gradient is 1 in 8. AS 1428.17 requires that the gradients and cross fails of the surface area within a landing or circulation space shall not exceed 1:40. Slopes of 1 in 100 to 1 in 40 are typically provided in surfaces, both internal and external. Surfaces with slopes of 1 in 20 (about 3°) to 1 in 8 are regarded as accessible ramps and require safety features such as handrails and tactile ground surface indicators. Some surfaces with slopes between these two ranges (i.e. 1 in 40 to 1 in 20) may warrant particular attention since they present a higher slip hazard but without having the safety features associated with ramps, e.g. handrails.

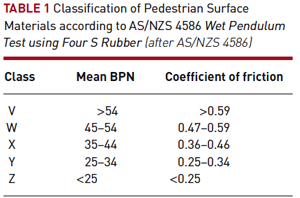

General Pedestrian Areas - These include areas such as courtyards, paths, walkways, driveways and the entrances to and circulation areas within publicly accessible buildings. When specifying polished concrete floors in general pedestrian areas, the guidance in HB 197 should be considered before specifying that the concrete have the appropriate Class V, W, X, Y or Z slip resistance in accordance with the wet pendulum test, Four S rubber Table 1. As the risk of slipping depends on many factors, the designer must consider to what extent various other design decisions will influence the overall risk of slipping when the concrete is wet (or contaminated).

External public areas and walkways generally require a Class W slip resistance surface, in order to ensure that the floor does not make a high contribution to the risk of slipping when wet. Class W surfaces were specified for all the external case studies examined in this Data Sheet (see Achieving Slip Resistance) and is recommended in HB 197. For entrance areas and other interior situations, such as bars/taverns and food court areas, where occasional contamination may occur, HB 197 recommends Class X surfaces. This is appropriate where the risk of slipping when wet is mitigated by promptly cleaning up spills and rainwater. For interior floors such as hotel foyers, offices, supermarket aisles and other public buildings/areas that are maintained in a clean and dry condition, the risk of contamination is very low and HB 197 recommends Class Z as an appropriate level of slip resistance.

Similarly, for polished concrete floors in residential applications where any spills are generally spot cleaned immediately to maintain the surface in a dry condition, Class Z would also be appropriate. Bathrooms and other 'wet' areas would generally require a Class X slip resistance.

While the wet pendulum test classifications are suitable for surfaces that have a maximum 1 in 20 slope, HB 197 recommends that the use of Class V for external ramps (i.e. steeper than 1 in 20). HB 197 also has an appendix that details a method for calculating the slip resistance class required for ramps. The procedure is as follows:

- Convert the required BPN value of the 'level' surface to a coefficient of friction, μ equal to 3P/(330-P), where P is the recommended BPN value for the level surface.

- To allow for the slope, increase the value of μ by an amount equal to the slopes (expressed as a percentage) multiplied by 0.0125.

- Convert the resulting coefficient of friction back to a BPN value equal to 330μ/ (3+μ)

- Select the appropriate slip resistance class.

The wet pendulum test may be used within a range of ±10° from level (slope of about 1 in 5.7).When assessing whether or not a sloping surface has adequate slip resistance, use the same procedure as in the examples above, and compare] the obtained result with the required BPN . The AS/NZS 4586 wet pendulum test can be used to check the compliance of new surfaces, while the AS/NZS 4663 wet pendulum test can be used to monitor changes in the slip resistance over time. For measuring the slip resistance of slopes steeper than 10°, a flatter area either at the top or bottom of the ramp (having the same surface texture and roughness as the slope) may need to be used for the test.

The wet pendulum test may be used within a range of ±10° from level (slope of about 1 in 5.7).When assessing whether or not a sloping surface has adequate slip resistance, use the same procedure as in the examples above, and compare] the obtained result with the required BPN . The AS/NZS 4586 wet pendulum test can be used to check the compliance of new surfaces, while the AS/NZS 4663 wet pendulum test can be used to monitor changes in the slip resistance over time. For measuring the slip resistance of slopes steeper than 10°, a flatter area either at the top or bottom of the ramp (having the same surface texture and roughness as the slope) may need to be used for the test.

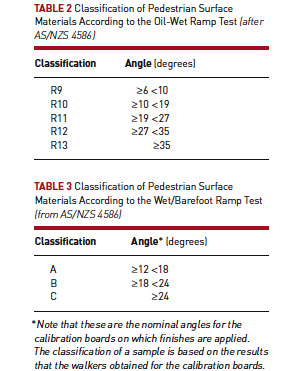

An alternate approach for ramps is to specify a Class R10 for dry internal ramps, or an R11 or R12 for external ramps Table 2. However, since the oil wet ramp test can only be conducted in the laboratory, compliance can only be assessed by secondary means such as wet pendulum tests and Rz surface roughness measurements. HB 197 contains recommendations for specific locations in terms of the R9 to R13 classifications. The angles do not relate to the steepness of the ramp that can be safely traversed.

Surfaces intended specifically for barefoot use - These should be specified as having a slip resistance Class A, B or C in accordance with AS/NZS 4586, wet/barefoot ramp test Table 3.

HB 197 contains recommendations for specific locations in terms of the A, B and C classifications. As with the oil-wet test, this test is used merely to assess the relative slip resistance of level surfaces. A higher classification may be appropriate in the case of sloping surfaces.Examples include:

Class A - Barefoot passages (mostly dry), changing and locker rooms, swimming pool floors where water depth >800 mm.

Class B - Barefoot passages not covered by Class A, shower rooms, pool surrounds, swimming pool floors where water depth <800 mm, toddlers’ paddling pools, some stairs leading into the water

Class C - Walk-through wading pools, sloping pool edges

Commercial and Industrial Applications As floors in many businesses and industrial applications can be subjected to a wide range of contaminants, their slip resistance is normally specified in accordance with the oil-wet ramp test Table 2. This test is used merely to assess the relative slip resistance of surfaces and the classifications are applicable to level surfaces. (Note: Oil-wet ramp test can only be conducted in the laboratory and compliance can only be assessed by secondary means such as the wet pendulum test). The wet pendulum test is the most appropriate means of specifying the slip resistance of concrete surfaces.

Table 5 in HB 197 gives guidance on suitable classifications for various commercial and industrial applications. HB 197 often recommends that surfaces should have a minimum displacement volume determined in accordance with AS 4568. Where it recommends a profiled surface, such as an R11 and V4 finish for car wash areas, it is best to go to a higher classification, in this case R12. Examples include:

Class R9 - Dining rooms, shops, operating theatres, hairdressing salons, classrooms.

Class R10 - Entrance areas in public buildings where moisture can enter from the outside. Social facilities (toilets, washrooms), some kitchens, most bathrooms and wash facilities, garages, and covered areas of multi-storey carparks.

Class R11 - Laundry areas, florist shops, vehicle repair workshops, aircraft hangers.

Class R12 - Most food processing/production facilities and large commercial kitchens.

Class R13 - Slaughtering, processing of meat, fish and vegetables

Article courtesy of Cement Concrete & Aggregates Australia website - www.ccaa.com.au

Article courtesy of Cement Concrete & Aggregates Australia website - www.ccaa.com.au