Epoxy Coatings

Epoxy Coatings, commonly referred to as 'painted concrete,' are a form of surface coating that are distinguished by their extended list of protective characteristics.

Characteristics of Epoxy Coatings

Epoxy coatings have a large number of benefitting characteristics, which make this concrete flooring system suitable for many uses. These characteristics include:

- Seamless and impervious membrane - dirt and bacteria cannot penetrate or settle in the floor. Therefore an epoxy floor is extremely hygienic and appropriate for locations that have very demanding sanitary requirements, such as pharmaceutical, cosmetic, food, beverage, chemical and electronics industries.

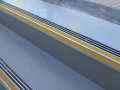

- Slip resistant - non-slip flakes can be incorporated into the coating to make the concrete floor slip resistant, which means an epoxy coating is perfect for pedestrian access areas, commercial kitchens and wet areas.

- Chemically resistant - an epoxy floor is protected from chemical corrosion and chemical deteriorations, including chemical attack from water, sugars, acids, solvents and caustics.

- Fire resistant - therefore suitable for fire escape routes, data rooms and sensitive storage areas

- Impact resistant - this indicates they are suitable for areas of industry where goods are handled in specific spaces, such as production lines, warehouses, loading bays, and where compressive loads are generated by the movement of goods on trucks, pallets, etc...

- High temperatures and thermal shock - favourable in areas where activities such as autoclaving, cooking, sterilising or blast freezing are carried out close by extreme temperatures or extreme variations of temperature.

Uses of Epoxy Coatings

Epoxy coatings are suitable for internal and external concrete floors in the residential, commercial and industrial environments.

Epoxy concrete floors are typically found in showrooms, living areas of the home, in offices and retail stores. They are also commonly used in shopping centres, restaurants, commercial kitchens and food preparation areas, cold storage rooms, plant rooms, workshop, health science, pharmaceuticals and community service areas.

Further Technical Information on Epoxy Coatings

- types of epoxy (two part, water based, etc...)

- other technical info that an architect/specifier would need